[ 63XC.COM | STORIES | RETROSCORCH ]

Ibis Scorcher Retrospective A decade ago, Ibis came up with an offroad fixed gear bike they called the Scorcher. It was a bike from a parallel universe where they do things differently, all slender tubes and graceful downsloping bars. Ibis' reputation for innovation and quality sold out the entire edition in double quick time, and there the story seemed to stop. Today, the idea of offroad fixed gear is gaining a toehold in the market. The Ibis team have gone their separate ways, but they're all still active in the industry. We decided it was time to take another look at their baby.

Founder: Scot Nicol 63xc.com: How did you get started in the mountainbike field? SN: I started Ibis after a trip to Crested Butte, Colorado. I was on a Cook Brothers Cruiser which I had modified with 18 gears and canti brakes. I met Joe Breeze, Charlie Cunningham, Gary Fisher, Charlie Kelly and a bunch of the other Marin folk. After I apprenticed with Joe and with Charlie C, I started Ibis in the spring of 81. The bikes were not really like Cunninghams or Breezers, but I took cues from both of them. 63xc.com: Ibis had a reputation for elegant, refined products with a sense of history and an unusually long lifespan. (I think I'm right in saying that the Bow-Ti is still in production somewhere.) That's a lot different from the industry's 'this year's model' philosophy. How come? SN: We always made the best bikes we could, never worried about model years. If we found a way to improve a bike, we did it. We didn't follow marketing cycles with planned obsolescence, and we resisted the trends toward unproven superlight tubings, the kind of things that maybe work fine on one-season race bikes. We made the bikes we wanted to ride, and we didn't want them to break. The industry is a lot different now, but I think we could maintain the same philosophy, the niche player thing, with a degree of success. People like Seven and Moots are doing it, and seem to be doing well. 63xc.com: How did you hook up with Wes Willits/Williams? Was he hired just for the Scorcher project, or did he do other work with the company? SN: I met Wes in Crested Butte, on one of my trips out. He asked me for an apprenticeship. If memory serves me right, he came down in late 84 or early 85. I do remember it was winter when he got here (California), and he froze his ass off. Which might seem a little funny coming from 9000 feet in Colorado to temperate sea level California, but it's the moisture in the air here--it cuts through to your bones. He worked here for ten years, was incredibly talented, and ended up running all the production.

63xc.com: Did the impetus for the Scorcher come from you, or from Wes? SN: It was Wes' idea. He was fiddling around with road bikes, converting them into fixed gear bikes, and sticking on the scorcher-style Torrington bars. He would get frames with significant clearance, then mount big 700C tires on them. Specialized Nimbus used to come in 43c which made the bike quite offroadable--I certainly don't need to tell you that! He made me one, I really liked it, still have it in fact, and we decided to do the limited production run. We also did similar small-run projects with trials bikes, tandems, singlespeeds, 'cross bikes. 63xc.com: Even today, the Scorcher would be an offbeat project--and back then, pre-singlespeed, it was downright eccentric. Whatever possessed you? SN: There were many offbeat things about Ibis. Remember, we were the guys who named a bike Hakkalugi. There was the Hand Job and the Toe Jam, the Cousin It, the Hot Unit, Wet Unit and Love Unit. We knew the Scorcher would be pretty far away from anything else out there, so we worked with our suppliers. They gave us good deals on the components, and we got them publicity. Because the bike was so unique, it got them a lot of press. We had magazine editors buying Scorchers because they were so cool, so different. 63xc.com: Someone told me the design of the Scorcher is based on an early TdeF winner bike. Is that true? SN: Maybe a better question for Wes. I just scored the L'Equipe three-volume set of 100 years of Tour history, and there's some similar bikes in there. But the scorchers were a little bit earlier, late 1800s, and I think that's where Wes got his inspiration from. For me, it was just intriguing to build a bike in that cool old-school style. 63xc.com: Many aspects of the Scorcher are unusual. The geometry is very laid-back, and the tubing looks slender by contemporary standards. Did you have to invest in special materials? Jigs? Constructional techniques? SN: Everything except the bars was pretty available. We used Tange road tubing in what were then common road sizes. The bike wasn't really that laid back. I forget the head and seat angles, but they were probably 72/73 or something close. The bikes were tig welded, so we didn't need lugs. It wasn't really much of a stretch for us to build. 63xc.com: How did you source the parts--the unusually slender cranks and so on? And--sorry if you've heard this one--where did you get those bars? SN: We manufactured the bars, using a talented local machinist/fabricator for the tube bending. The components were a pain in the rear to find, but, with a bit of digging, we found them all. 63xc.com: I know of five Scorchers on the road for sure, and have possible sightings of two more. That's an unusual survival rate, given that you only built 100 in the first place. Any comments on the longevity of the bike? SN: I have never heard of a broken one. Not to say there aren't any, I've just never heard of one. I'd be willing to bet that most of them are still rideable. You see them on eBay occasionally. 63xc.com: Now that more and more builders and riders are interested in taking fixed gear bikes offroad, how does it feel to have been ahead of your time? SN: I think all these things are cyclic. Most cool stuff has been done before, in some way, shape or form. I could name a few examples of things we did that came around again later. And probably will again. I don't feel we were big innovators. But we were having fun, following our hearts, being passionate and real about what we did. Sure, we had to sell stuff to pay the rent, but we really believed in what we were doing, and people recognized that. 63xc.com: What's the present status of Ibis? SN: In 2000, Ibis was taken over by terrorists, or you could say evildoers. The Ibis is a beautiful bird in flight, but the new owners crashed it straight into the ground. 63xc.com: Will it ever fly again? SN: The possibility exists.

Designer: Wes Williams 63xc.com: Where did your interest in offroad fixed gear bikes come from? WW: In 1981 I read a book called 'King of the Road' by Andrew Ritchey, which had come out a few years before. It mentioned scorchers, and the type of people that rode them, back in the late 19th century. 63xc.com: How do you tell a scorcher? What makes a scorcher? WW: Well, at that time there were pedestrians and there were people on horses. These people coming through on bikes, they were a terror. 63xc.com: So, they kind of shook things up? WW: Yeah, they were so-called because they scorched through crowds of pedestrians... 63xc.com: It sounds like they quite enjoyed what we in this country would call winding people up? WW: Precisely. It's just like us big wheelers know about the 26" wheels, that we feel so far superior to the other person, we can do circles around them... 63xc.com: What about the design of these early scorcher bikes? Was there a particular design that was associated with them? WW: Well, I'd been riding lightweight bikes offroad since 1972. The design of the Ibis Scorcher followed that of a Motobecane that I built up in 1982. I built it out of junk, and I still have it on my wall. 63xc.com: Now, that's the same kind of a deal as the one that Bob Poor rides, isn't it? WW: Same kind of a deal, but his frame is a little newer than mine. 63xc.com: So this is a road frame with quite thin tubing? WW: Mine is 6lbs. They're not road frames, they're touring frames from the 60s and 70s. 63xc.com: I guess we'd use the terminology a bit differently in this country. What I mean is, it was never designed as an offroad bicycle. WW: Well, the French had rougher roads, as you know. The offset on the French forks was two and a half inches, whereas the British was two. My first ride on this thing was on a singletrack trail called the Lower Loop, in 1982. 63xc.com: And that's in Crested Butte, the epicentre of Colorado mountainbiking? WW: Oh yeah. I've been scorching for 20 years now. 63xc.com: So when you look at the Motobecane, and you compare it with your own Scorcher design, what are the things you changed from that original shape? WW: Well, I put a sloping top tube in it. We used double-butted and thinner tubing, so we got a 3 1/2 or 4lb frame. And it only fit a 45c tyre. 63xc.com: I hadn't realised it was so light... I should tell you that my own scorcher, as you would say, is a Hopper from the 1950s. The frame weighs just under eight pounds. It's plaingauge 531. WW: And they ride great! Those heavy frames ride great! They absorb all the shock, they don't transmit it. I've got a couple of frames in front of my shop right now that are scorchable. One is an old Schwinn Japanese 70s touring bike with lugs, and it probably weighs 6lb. There's nothing better than that for this application. 63xc.com: So, a scorchable frame would be probably... 60s or 70s, older, heavier, with big clearances... WW: It would probably be built for a 27" rim. We'd put 700c wheels on there with big tyres, and we'd fit fenders... mudguards, is that what you guys call them? 63xc.com: Yeah, very good... WW: People see me riding one of these things and they think I'm some Brit guy, you know...

63xc.com: The Ibis Scorcher has a couple of features that look really distinctive. The handlebars, for instance. Where did you get the idea? WW: That's what they did back in the day, back in 1895. I just copied what they were doing. 63xc.com: That really long, elegant stem? WW: That was my own deal. After years of having too short a position with those bars on modern stems, the 30° by 165mm stem has become my standard. I've probably made a hundred of those stems. 63xc.com: Yah. WW: There's a hundred scorchers in Crested Butte, by the way. 63xc.com: I know from exchanging emails with Bob Poor that there's a little subculture there. I hadn't realised that it was 100 riders. You have quite a community going. How many of 'em are riding Ibis Scorchers? WW: Only I have one. 63xc.com: You were production manager at Ibis, weren't you? WW: I was there nine years. It was just three of us for three years, then six of us for a couple of years, and then we went through like 50 people real fast. We were up to 25 employees and 6000 sq ft. 63xc.com: I know you did quite a short production run of Scorchers... WW: 100 bikes and three others. 63xc.com: But I've been able to track down seven via the Internet, which suggests that most of 'em are probably still on the road. They seem to have a long lifespan. WW: My own one, which I built after the fact, I've repainted four times. It just goes on and on. It's beautiful. 63xc.com: I was surprised that there's no special Scorcher page on the Willits Brand site. Any intention of putting them back into production? WW: Well, they're not big sellers. I sell mostly touring bikes, what I call Safeties. People that buy scorchers don't want to spend $1000 or $2000 dollars, they want to spend $100. 63xc.com: Real community stuff, in other words? WW: Well, if I had people banging on the door for fixed gear bikes, I'd sell 'em.

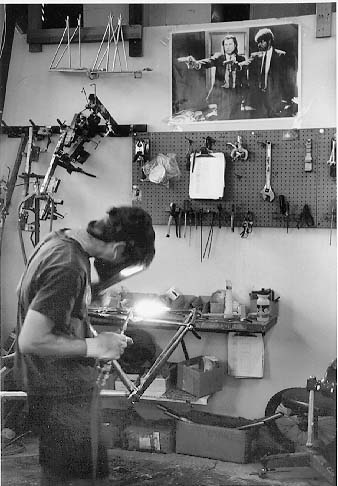

Builder: Jay Sexton Will, here are my thoughts. The entire batch of Scorchers went out the door in late 1993 or early 1994. They weren't any more difficult to build than any of our other bikes and required no special jigs or fixtures that I can recall, although the Tange tubing was a bit harder to weld than usual. I needed a fair amount of practice before I felt confident enough to weld a bike together. Meanwhile, I blew quite a few holes in that thin tubing. However, I'm still riding a frame from that time that has held together through ten years of abuse, so I must have done something right. The raw tubes would be divided up into top tubes, down tubes, seat tubes, then mitred accordingly, taking into account where the butting would go. The frame jig would be set with the correct geometry, the BB shell and head tube clamped in, and the seat tube would be the first one on. After cutting one tube and checking the mitre fit, I would cut all the seat tubes. Top and down tubes were done the same way: one tube for fit, then cut the rest. We had a milling machine set up with a hole saw and a clamping fixture for mitering the three main tubes. It was generally more efficient to do batches, and, since the Scorchers were made in three different sizes, this method worked especially well. As you know, we made 25 each of small and large, and 50 mediums. The chainstays and seat stays were next. Again, no special fixtures. Dropout ends were cut to match the internal diameter of the chainstay, then welded into place. Once the dropouts were welded into the mitred ends of the chainstays, I would bend and crimp the stays before taking them to a mitering fixture for fitting to the BB shell. Both stays were clamped at once, so we could do them both at the same time with a hole saw that was the same diameter as the shell. We had another fixture for mitering seat stays, but they were cut to match the seat tube diameter. I remember days where all I did was mitre stays--fortunately, not every day! Most of the shop machine tools were ancient. The story I heard is that they were purchased from the east coast and shipped west. The hand-cranked horizontal milling machine that we used for the chainstays required brute strength to work. This thing built muscle! There was a huge J&L lathe that I loved to operate. It was way overkill for the shop, but man was it impressive. I think it weighed something like two and a half tons! Once all the tubes and stays had been mitered, they were all deburred, then cleaned and weld-prepped inside and out. We'd clamp them in a frame jig, tack them together, one by one, then pass them on to Wes. Wes did the majority of the welding at the time, and in fact I believe he welded all the Scorchers. Rob Roberson did a final braze on the dropouts and any other fittings that needed it. Then, after a final finish and paint prep, they'd get painted by Erica before assembly. Of course there were other folks working on other parts of the process. I wasn't around for the final assembly, so I don't know who made the cranks or the hubs. The bars were designed after a bar made by Torrington, a company who were active in the 30s through 50s--tho' Wes could probably give you more information on that. The atmosphere in the shop was always fun. We were all there due to our passion for bicycles. Scot has an offbeat sense of humor, so we were almost encouraged to express ourselves in an eccentric fashion. Basically we could be ourselves as long as we got the job done, were safe, and treated each other fairly. Of course there were conflicts, but that is just the nature of life. Ibis was the best job I ever had. You think the shop floor photos were wild? You should have seen the bathroom! Clean, but wow, talk about decorations! Road signs, newpaper articles and headlines, jokes... A visitor would stay in the bathroom just to read the walls. [ TOP ] |

63xc.com thanks...

Jay Sexton, former Ibis builder, and a great source of contacts.

Scot Nicol, Ibis founder, MTB HoF inductee, and author of our metallurgy primer.

Wes Williams, Scorcher designer, 29" innovator, owner of Willits Brand Cycles, and reigning champion of the Interbike pool slalom.

Tom Nakashima, Ren Finley and George Leakos, Scorcher owners.

Dennis Bean- Larson of the Fixed Gear Gallery.

Date

v1.0 written August 2003

Photos

Ibis workshop ca. 1998 © Scot Nicol.

Pacific Scorcher © Tom Nakashima.

Green Scorcher © Ren Finley.

Back porch Scorcher © George Leakos.

Several of these shots first appeared on Dennis Bean- Larson's excellent site.

Related

Wes Williams is selling his Scorcher, #103. Serious buyers can phone him at his shop on US 970 349 0130.

Bob Poor rides a Crested Butte scorcher as described in the text.

Mailing list

Join the 63xc.com list.