[ 63XC.COM | STORIES | STEVE POTTS ]

Steve Potts interviewed

After scheduling problems, equipment failures and sundry VOIP-related computer hassles, we finally managed to get some time on a bad line with MTB pioneer Steve Potts in Marin County, California. Steve originally vouchsafed us 10 minutes but in the end gracefully allowed us a half hour of his time. We discussed his background, his experiences at WTB, his present work as a lone builder, and his thoughts about the future of mountainbiking. Oh, and we got to talk about the significance of titanium, too.

63xc.com: Steve, you were one of the pioneers of mountainbiking. You were in at the very beginning, the cruiser-on-a-firetrail days. SP: I started back when I was quite young, before high school. When I got to high school in 1967 I was already starting to retrofit and rebuild oldworld paperboy bikes. I did that all through the 60s and 70s. 63xc.com: Those would be the classic Schwinn cruisers? SP: Schwinns and Rollfasts and Colsons. All the old fat tire bikes. I lived at the base of Mt Tamalpais, and that was a great place for a boy to roam around and have adventures. 63xc.com: Did you learn brazing and so on from machinists, or are you self-taught? SP: I had good instructors in high school, and at college I took machine shop and metallurgy. But there was also my Marin County background. There were a lot of talented people around with little machine shops. For instance, my father had built telescopes with Joe Breeze's dad when they were young. They both had incredible skills to pass on. The biggest lesson was doing stuff, time after time. 63xc.com: Did those learning relationships continue among the pioneer mountainbikers? SP: They did. I went to high school with Joe Breeze, and helped him in his shop. I learned a lot with him and with Tom Ritchey too. 63xc.com: My understanding is that WTB was quite a loose grouping, that you and Charlie Cunningham worked in parallel but you had your own projects and ideas going. Is that the case? SP: We were partners in WTB, but over the years we always collaborated on fun technical projects. 63xc.com: Were you frustrated when WTB commodified your ideas? SP: No. Our goal was always to have two lines. We'd have a premium product made in the US, like the GreaseGuard headsets that we had built by Chris King. At the same time we'd licence the technology to a company like SunTour, who would mass-market it to a much larger audience. We always aimed to keep our own technology at the high end, whether with GreaseGuard headsets, GreaseGuard BBs, rollercam brakes... That always helped to drive standards in the mass market line. 63xc.com: It must have worked -- a lot of WTB tech from the late 80s is still out there. SP: It worked pretty well. Could have been better, but I guess we did the best we could do at the time. 63xc.com: How long have you been Steve Potts Bicycles again, rather than Wilderness Trail Bikes? SP: Well, it's about three years since Charlie and I left WTB -- but then, it was Steve Potts Bicycles before it was ever WTB. During the WTB years, I just put my name on the bikes that I continued to build.

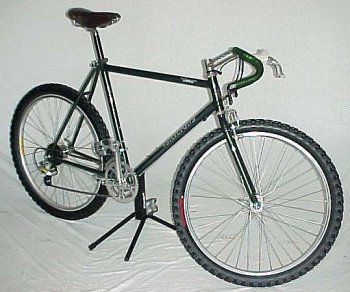

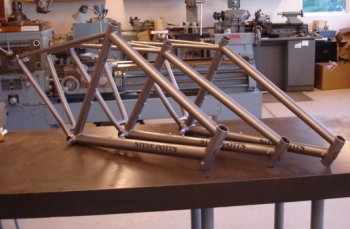

63xc.com: Are we going to see more of your dropbar MTBs? You probably know that the DirtDrop became a cult item on eBay. SP: I get a lot of email from people looking for those. Those things work well, and they have a real place in the market. 63xc.com: So, if you've left the factories behind, where are you working now? I imagine you're in the middle of your shop and there are five bikes on stands and your brazing torch is fired up... SP: I have a really nice clean 2000 ft workshop at my home. Right now, tho, I came in the house because I was expecting your call. 63xc.com: What are you working on these days? SP: I'm making some MTBs, some cross bikes, some road and travel bikes. My travel bikes are fully-functional racebikes, roadbikes, MTBs that can be taken apart and put in a bag with not a bit of compromise. Plus I'm building the Silk Ti and Bow Ti for John Castellano now. 63xc.com: The ones that Ibis used to build? SP: John made them with Ibis, but he owns the patent--the pivotless 5" travel thing. We're doing it on a much smaller, more intimate level to reach all the hardcore customers. 63xc.com: You're also using titanium in your own projects. Do you feel that there's stuff you can do with Ti that you can't do with steel? SP: Titanium is an amazing material. It's extremely durable, it's reliable and strong and takes an incredible amount of abuse. Plus it doesn't corrode. We're on the north coast of California here. Moisture from the ocean can really destroy a steel bike. The corrosive protection is a real plus. 63xc.com: I guess also it's appealing to the lone craftsman because it's hard to do industrial-scale production with it. It seems to lend itself more to a lone guy who takes care over process. SP: Titanium is hard to work with. It's hard on tools, everything has to be perfectly clean, your heat and welding processes have to be well- thought-out because you can destroy an expensive piece very easily if you don't know what you're doing. I think the reason why some of the best Ti fabrication is done in the US is that builders here are into doing it right and they understand what needs to be done. Usually one person sees the process through from start to finish. In a big factory, where a different person does each operation, it's easy to lose sight of the whole process. 63xc.com: I think it's hard to motivate people on a salary to care in that way. That level of dedication tends to belong to the self-employed. Actually, I guess that's true of bike building in general, not just titanium fabrication. SP: It's true wherever you look. You can buy good mass-produced stuff, but a lot of the money you spend goes into advertising and promotion and all the logistics of a large company. It's a different kind of value when you go to a custom builder. When you hire a small builder, what you're getting is his time, his hours spent building a beautiful hand-built brame. 63xc.com: Who are your customers? SP: The guys who come to me have been through everything, they've bought all the bells and whistles and they've found that it didn't work as well or didn't last as long or didn't ride as great as they expected. It didn't give them what they wanted. They look at my bikes with a microscope, inside and out. They're looking at the welds, they're looking at the alignment, they're looking at the finish, they're looking inside the tubes to see if there's any colour from the welding... they want a perfect bike. That's a harder level to reach but it's what I enjoy doing.

63xc.com: Having been involved with MTBs for more than 30 years you have a long-term perspective on the sport. Any thoughts about the way it's developing at the moment? SP: The market will always go through cycles -- no pun intended -- and there will always be the larger companies that do a great job for the most part supplying affordable high quality bicycles at different price points for different market segments -- cross country, full suspension, commuter, road, cross, etc... Then you will have the small builders to fill in that market as the user matures in his or her cycling needs. The cycling experience today is usually introduced in a fun, recreational way, and there are more organized outfitting companies that are really helping people have a fun, safe, and exhilarating experience in the sport. The bottom line is that the bicycle is here to stay. 63xc.com: Thanks, Steve.

[ TOP ] |

Writer

Will Meister

Images

Photos are © Steve Potts except for the 1990 XC racer, which is courtesy of First Flight Bikes.

Date

Version 1 February 2006

Related

Steve has his own site here...

...plus here's his entry in the MTB HOF.

Mailing list

Join the 63xc.com list.